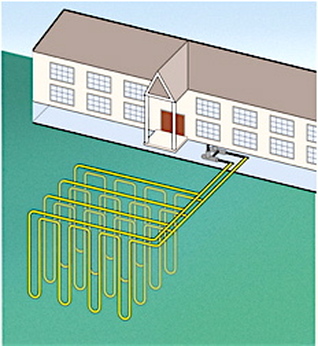

Vertical Bores as closed loop heat exchangers--

These kinds of ground loops are bored in the earth, straight down, to a depth of 150-300 feet. After the drilling equipment is withdrawn, a doubled length of HDPE (high density polyethylene) pipe with a U-bend-return fitting at the end is lowered into the bore and bottomed there. A dense grout mixture is filled from the bottom, upward, which establishes a solid encasement for the HDPE pipe.

|

The two ends at the surface (supply and return) are trimmed, later to be coupled with larger headers serving adjacent bores. Boreholes need to be separated laterally by 15-20 feet. When properly completed with grout, they act like cylinder-shaped thermal magnets to the ground's heat. In heating, the ground loop's fluid yields it's heat contribution at the heat pump, returning to the ground in a cooler condition by 4-6°F. This places a thermal draw on the grout, which cools and places a thermal draw on surrounding soil or rock. In cooling, warmer ground loop fluid dissipates its heat load to the grout and then outward to soil or rock.

Depending on the sizing and geophysics, rejection of summer heat into the bores can have a bit of a "thermal flywheel" effect, where the ground temperature will be somewhat elevated by the first weeks of the heating season. The flywheel effect in reverse can also be true at the end of a long heating season, having left the ground around the bores cooler. The rapidity of your summer's first cooling may find even better heat loss, thus shortening the heat pump's running time and saving you even more money. Vertical bores cost more than horizontal loop fields but they bring significant advantages: • More stable underground temperatures, down deep • Better conductivity in what is likely to be rock • A smaller "footprint" than horizontal loop fields Therefore, a greater flexibility exists for installations in dense residential neighborhoods, for commercial building projects, multi-family housing, and large, institutional buildings. The number of boreholes and their depth depend on the heating/cooling load of the intended building or retrofit structure. Proper mechanical engineering is paramount. (Above) Used and new drill bits used by Palace Geothermal Drilling in South Jordan, UT. (Below) Palace's drilling rig in action. Small sizes like this are highly maneuverable, making a wider retrofit market possible, drilling in side yards as well as front and backyards of existing homes. |

(Above) A fluid treatment common to all closed loop ground source heat pump systems. A mixture of 10-20% into the total fluid volume provides freeze protection, chemical stability, and insures no biologic growth to harm the heat conduction process.

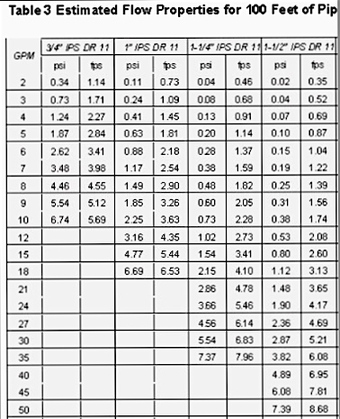

While antifreeze may seem unusual in such an application, fluid temperatures can approach freezing, and in the high twenties a compressor "lock-out" condition might occur, halting all ground loop heat gathering. (Left) Adequate pumping rate within ground loop pipe insures a turbulent and not laminar flow. Turbulence is best because it "scrapes" more ground heat from the inside surfaces of the pipe. Laminar flow can cause much fluid in the center of the bore to not have much contact with pipe walls. The name of this game is heat exchange, all the way. |