Other water-based heat pump heat sources (open loops)--

This is the only ground source heat pump configuration that does not feature a closed loop configuration. There is no treated fluid mixed in with that which circulates to and from the main loop's heat exchanger inside the heat pump. This introduces engineering and maintenance challenges not present in treated, closed loop systems. The challenges:

• microbiota in the water that can coat lines, pump vanes, and the heat exchanger itself

• sand and larger grit that can wear through pumping vanes and harm the inside coating of the heat exchanger

• providing enough filtration and checking to see than (the above) has not happened—greater maintenance

Fortunately, the SCW (Standing Column Well) may be armed against much of these dangers. The main fluid heat exchanger can be metallurgically plated to resist corrosion and wear. And a typical SCW (like its domestic residential cousin) does not pump from the bottom of the column, picking up too much sand. As long as the flow of water from the SCW can sustain a pumping action of 3 gallons per minute per ton of capacity for long run times, a well will suffice.

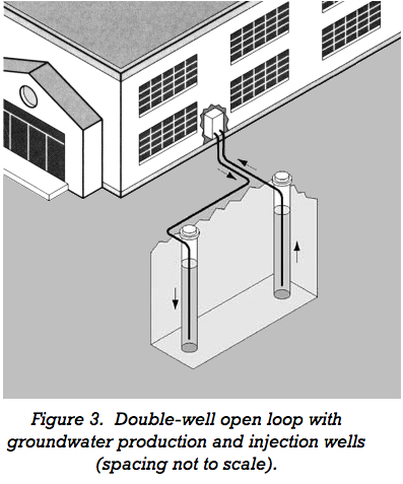

The responsible thing to do is to drill TWO wells— one for supply and the other to return the fluid volume underground to the aquifer. To "Pump and Dump;" that is, to put the water out into surface drainage (if you are not a year-round agricultural user) is irresponsible. You will obtain the highest potential efficiency from your water-based heat pump with an open loop arrangement. Do the right thing. (See a variation on the SCW, below the double-well graphic)

• microbiota in the water that can coat lines, pump vanes, and the heat exchanger itself

• sand and larger grit that can wear through pumping vanes and harm the inside coating of the heat exchanger

• providing enough filtration and checking to see than (the above) has not happened—greater maintenance

Fortunately, the SCW (Standing Column Well) may be armed against much of these dangers. The main fluid heat exchanger can be metallurgically plated to resist corrosion and wear. And a typical SCW (like its domestic residential cousin) does not pump from the bottom of the column, picking up too much sand. As long as the flow of water from the SCW can sustain a pumping action of 3 gallons per minute per ton of capacity for long run times, a well will suffice.

The responsible thing to do is to drill TWO wells— one for supply and the other to return the fluid volume underground to the aquifer. To "Pump and Dump;" that is, to put the water out into surface drainage (if you are not a year-round agricultural user) is irresponsible. You will obtain the highest potential efficiency from your water-based heat pump with an open loop arrangement. Do the right thing. (See a variation on the SCW, below the double-well graphic)

|

Double-well systems, with separate supply and discharge wells(Figure 3), may be required where environmental regulations limit or prohibit discharge into surface water bodies or drainage fields. The distance between the production and injection wells is an important design consideration. It is not necessary to completely prevent flow from the injection well to the production well, but simply to make sure that any flow between the wells is sufficiently low that discharged water arrives at the production well at a temperature at nearly the same temperature as the aquifer. Well spacing typically will be in the range of 200 to 600 feet, depending on the maximum system cooling or heating load, the typical duration of the maximum load, and the thickness and natural flow rate of the aquifer. |

[From a report by the Virginia Department of Mines and Minerals, and the U.S. Department of Energy]

A Variation on the Standing Column Well at Feather River College

An artesian well serving ___ heat pumps in a _____ sf building in Quincy, CA--

An artesian well serving ___ heat pumps in a _____ sf building in Quincy, CA--

Feather River Community College in Quincy, CA has a history of ground source heat pump use for campus buildings. Most of the campus was converted from electrical resistance heating and air conditioning in the 90s to a combination of vertical bore and horizontal closed loops to condition a number of buildings. Energy and money saved was substantial.

The campus is now (Fall, 2011) about to occupy its recently completed Library-Learning Resource Building which will again use ground source heat pump technology. But the twist is that during early site preparation for construction an artesian well was uncovered that held the possibility of an open loop system with little necessary pumping required.

Plans were changed, mid-stream in the construction project (pun intended) and today this building has the option of using surface-stored well water or direct draw from the well. A re-injection mechanism was not necessary since the source of the well is in a ravine drained by a near-perennial stream. Any discharged water is drained to this stream less than 100 feet from the point where it surfaced as an artesian flow.

The campus is now (Fall, 2011) about to occupy its recently completed Library-Learning Resource Building which will again use ground source heat pump technology. But the twist is that during early site preparation for construction an artesian well was uncovered that held the possibility of an open loop system with little necessary pumping required.

Plans were changed, mid-stream in the construction project (pun intended) and today this building has the option of using surface-stored well water or direct draw from the well. A re-injection mechanism was not necessary since the source of the well is in a ravine drained by a near-perennial stream. Any discharged water is drained to this stream less than 100 feet from the point where it surfaced as an artesian flow.

|

The new building on the FRC campus in Quincy, CA

One of the water-based, single stage heat pumps in the building's mechanical room taps the circulating fresh water supply and return lines

In June, 2011 summer cooling mode, incoming water to the mechanical room is 48°F

|

(Above and Below)

Artesian well water can be piped through the mechanical room and dumped in the stream, or sent to this tank for storage and recirculation to minimize pumping and water use After passage through those heat pumps that are in cooling operation, outgoing water exits at 59°F

|